General Electric F404-GE-400 & 402Jet Engine

Specifications: F404-GE-400

Thrust (lb): 16,000

Airflow (lb/sec): 142

Weight (lb): 2,185

Maximum Diameter (in): 35

Pressure Ratio: 25 to 1

Specifications: F404-GE-402

Thrust (lb) 17,700

Airflow (lb/sec) 146

Weight (lb) 2,282

Maximum Diameter (in) 35

Pressure Ratio 26 to 1

Milestones: F404

F404 Entered U.S. Navy Service 1981

First Operational U.S. marine Squadron 1983

First Operational Carrier Squadron 1985

First Delivery of F404-402 EPE 1991

3,000th F404 Engine Delivery 1994

F404 Attained Five Million Flight Hours 1995

Courtesy General Electric

General Electric F110-GE-129 Jet Engine

Specifications: F110-GE-129

Thrust Class (lb/kN) 29,000/129*

Length (in/m) 181.9/4.6

Max. Diameter (in/m) 46.5/1.2

Air Flow Class (lb/s; kg/s) 270; 122.4*

Bypass Ratio 0.76

Engine Controls FADEC (normal) mode, plus two hybrid

modes with pure hydromechanical backup mode

* The F110-GE-129 engine, as delivered, has consistently

demonstrated 31,000 lb/138kN thrust at sea level static

uninstalled and 270 lb/s flow.

Courtesy General Electric

General electric F414-GE-400 Jet engine

Specifications: F414-GE-400

Thrust Class (lb) 22,000

Weight (lb) 2,445

Maximum Diameter (in.) 35

Pressure Ratio 30 to 1

Thrust-to-Weight 9 to 1

Overview

Specifications

Milestones: F414-GE-400

Engineering and Manufacturing Development (EMD) began June 1992

First Engine To Test May 1993

PFQ (Flight Qualification) September 1995

First F414 Flight November 1995

LPDQ (Low Rate Production Qualification September

1996

Production Begins June 1998

Courtesy General Electric

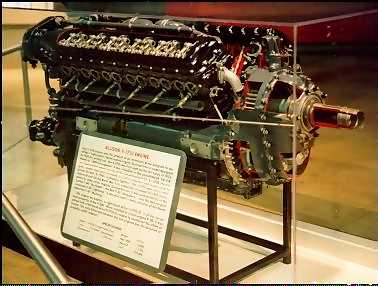

Allison V-1710 Aircraft Engine

The V-1710 engine was the first product of an extensive Army program to develop

a high-power, liquid-cooled engine. Derived from a model designed in 1930 for airship use,

the V-1710 was first used by the Air Corps in 1932. Rated at 1,000 horsepower, it was

installed in the Consolidated XA-11A, an experimental attack version of the Consolidated

P-25. By 1938, the engine's output had been increased to 1,150 horsepower and was used to

power the Bell X/YFM-1 multiplace fighters. The V-1710 was continually improved and during

World War II its output was increased to 1,475 horsepower in some series engines. During

the war it was used primarily in the Curtiss P-40 "Warhawk",

the Bell P-39 "Airacobra", and the twin-engine Lockheed P-38 "Lightning". It was also used in early versions

of the North American P-51 "Mustang".

The engine on display, a right-hand drive V-1710-51, is of the series used primarily in

the P-38G. When installed in a twin-engine P-38, it was paired with

a left-hand drive V-1710-55 engine to counteract the effect of torque. The only difference

between the two engines was the direction of propeller-shaft rotation.

SPECIFICATIONS

Model: V-1710-51 (right-hand drive)

Type: 12 cylinder, supercharged

Displacement: 1,710 cu.in.

Weight: 1,345 lbs.

Maximum RPM: 3,000

Maximum Horsepower: 1,325

Cost: $19,000 (engine only)

Allison engine installation on P-51A

Courtesy U. S. Air Force Museum

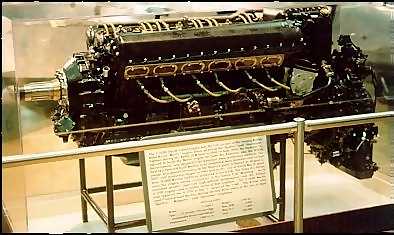

Packard V-1650 "Merlin" Engine

The V-1650 liquid-cooled engine was the U.S. version of the famous

British Rolls-Royce "Merlin" engine which powered the "Spitfire" and

"Hurricane" fighters during the Battle of Britain in 1940. In Sept. 1940, the

Packard Co. agreed to build the Merlin engine for both the American and the British

Governments, and adapted it for American mass-production methods. The first two

Packard-built Merlins to be completed were demonstrated on test stands at a special

ceremony at the Packard plant in Detroit on August 2, 1941. Full production began in 1942

and by the end of World War II, more than 16,000 Merlins had been produced in the U.S.A.

The Army Air Forces used the engine almost exclusively in the famed P-51

"Mustang", for it provided greatly improved high-altitude performance over

the Allison V-1710 engine used in earlier

series of the airplane. The V-1650 Merlin also replaced the V-1710 in the "F"

series of the P-40. The British also used Packard-built Merlins during the last three

years of the war in their "Spitfire", "Mosquito", and

"Lancaster" airplanes.

The V-1650 liquid-cooled engine was the U.S. version of the famous

British Rolls-Royce "Merlin" engine which powered the "Spitfire" and

"Hurricane" fighters during the Battle of Britain in 1940. In Sept. 1940, the

Packard Co. agreed to build the Merlin engine for both the American and the British

Governments, and adapted it for American mass-production methods. The first two

Packard-built Merlins to be completed were demonstrated on test stands at a special

ceremony at the Packard plant in Detroit on August 2, 1941. Full production began in 1942

and by the end of World War II, more than 16,000 Merlins had been produced in the U.S.A.

The Army Air Forces used the engine almost exclusively in the famed P-51

"Mustang", for it provided greatly improved high-altitude performance over

the Allison V-1710 engine used in earlier

series of the airplane. The V-1650 Merlin also replaced the V-1710 in the "F"

series of the P-40. The British also used Packard-built Merlins during the last three

years of the war in their "Spitfire", "Mosquito", and

"Lancaster" airplanes.

SPECIFICATIONS

Model: V-1650-7

Type: 12-cylinder with two-stage mechanically-driven supercharger

Displacement: 1,649 cu.in.

Weight: 1,690 lbs.

Max. RPM: 3,000

Max. HP: 1,695

Cost: $25,000

Courtesy U. S. Air Force Museum

Pratt and Whitney R-2800-21 Engine

Pratt and Whitney's R-2800 cu in. (45.9 L) was America's first 18

cylinder radial, the Double Wasp. Much smaller than the world's only other modern

eighteen, the Gnome-Rhone 18L of 3,442 cu in. (56.4 L), it was nevertheless more powerful,

and heat dissipation was correspondingly more of a problem. This meant that, for the

R-2800, the cast or forged cooling fins that had served so well in the past had to be

discarded. The cooling fins needed were so thin and fine-pitched that they had to be

machined from the solid metal of the head forging. All the fins were cut together. A gang

of milling saws was automatically guided as it fed across the head so that the bottom of

the grooves rose and fell to make the roots of the fins follow the contour of the head.

The results were worth the trouble as it was a case of designing an engine component that

could only be made by a new method and then keeping everything crossed until the new

method proved to be practical. In addition to the new head design, the Double Wasp had

probably the most scientific baffling yet to direct the flow of cooling air, more so even

than the

excellent arrangements on the Ranger inline air-cooled engines.

2000 hp was obtained from the R-2800 with 1 hp/1.4 cu in. (43.6 hp/L) of displacement. In

1939, when the R-2800 was introduced, no other aircooled engine came close to this figure,

and even liquid-cooled ones barely matched it. The designing of conventional air-cooled

radial engines had become so scientific and systematic by 1939 that the Double Wasp was

introduced at a power rating that was not amenable to anything like the developmental

power increases that had been common with earlier engines. It went to 2,100 hp in 1941 and

to 2,400 late in the war, but that was all for production models. Experimental models, as

always, were coaxed into giving more power, one fan-cooled subtype producing 2,800 hp, but

in general the R-2800 was a rather fully developed powerplant right from the beginning.

It was exclusively a powerplant for fighters and medium bombers during the war, being used

in the P-47 , the F6F

Hellcat, and the F4U Corsair , and also in the

B-26 and A-26 twin engine mediums. Post-war its reliability commended its use for

long-range patrol planes and for the DC-6, Constellation, Martin 404, and Convair

transports. This last application is noteworthy, since these were twin-engine craft of

size, passenger capacity, and high wing loading comparable with the DC-4 and the first

Constellations.

Two engines were all right for transports with the DC-3's moderate wing loading, and the

high wing loading of the DC-4 was safe enough when there were four engines, but all that

weight with only two engines seemed like tempting fate. However, the led from fatigue

after a while.) The Convairs were just as good in their way as the four-engine transports.

A well engineered installation and good controls were probably what made the difference;

had the Convair encountered as many engine failures as did Curtiss-Wright's deplorable

C-46 Commando, it would have been a sad story.

When the USA went to war in December 1941 there were very quickly some major changes in

philosophy. Such

long-established engines as the Cyclone and Twin Wasp were re-rated on fuel of much higher

anti-knock value to give considerably more power. Perhaps the most outstanding example was

the great R-2800 Double Wasp, which went into production in 1940 for the B-26 Marauder at

1,850 hp and by 1944 was in service in late model P-47

Thunderbolts (and other aircraft) at a rating of 2,800 (experimental) hp on 115-grade

fuel with water injection. Of course, all engines naturally grow in power with

development, but a major war demands the utmost performance from engines fitted to

aircraft whose life in front-line service was unlikely to exceed 50 hours' flying, over a

period of only a month or two.

In peace time the call was for reliability over a period of perhaps a dozen years. And of

course a pilot in combat has no time to fiddle endlessly with a fistful of engine controls

in order to maintain the optimum engine operating conditions, and bearing in mind the rate

at which aircrew had to be produced in wartime he probably did not have the knowledge of

how to do this either.

Specifications:

Pratt and Whitney R-2800 Double Wasp - USA

Date: ----------------- 1939

Cylinders: ------------ 18

Configuration: -------- Radial, Air cooled

Horsepower: ---------- 2000

R.P.M.: --------------- 2400

Bore and Stroke: ----- 5.8 in. (146 mm) x 6 in. (152 mm)

Displacement:--------- 2,800 cu. in. (45.9 liters)

Weight: --------------- 2,350 lbs. (1,068 kg)

Courtesy U. S. Air Force Musemu

General Electric F110-GE-400 Jet engine

Specifications: F110-GE-400

Thrust Class (lb) 27,000

Length (in) 232

Max. Diameter (in) 46.5

Air Flow Class (lb/sec) 270

Bypass Ratio 0.87

Engine Controls Electronic primary control -

Hydromechanical backup

Courtesy General Electric